Sound, no matter how complex, is just waves like the ripples in a pond. It can be considered as the displacement of molecules from their place of rest. A more technical definition would be: Sound is a series of compression and rarefaction waves in a substance, solid, liquid or generally in our experience, gas. Our aim in recording is to precisely reproduce these waves in another place and/or at a different time. As exact, absolutely precise reproduction can't be done even today, we must be satisfied with successive approximations and keep aiming to improve. A cheap, bad telephone will make something that sounds "sort of" like you. A mechanical phonograph will sound "better" but still not exactly the same as you. We can successively improve our approximations until, with modern speakers, decent amps and CD quality recording it would be very difficult to tell which was "real" you or the recording. But you might still be able to tell that there was a difference.

First exercise for students—take an inflated balloon, hold it in front of your face, and sing at it. You can feel the vibrations through your fingertips (and in good lighting, by singing loudly, watch them travel over the surface). As the sound hit's the balloon it wiggles, which is about how the ear drum works. If we were able to attach a needle to our balloon with glue or tape, we could have made it inscribe a wiggly line on a soot-covered piece of paper, which shows that we can make a record of the sound. This would demonstrate that enough energy is being transferred to do mechanical work.

Air seems very easy to move, but trying to move it fast requires energy—as any manufacturer of sports cars could tell you. They call it air resistance, we call it acoustic impedance, but it comes down to the same thing. Despite what residents of Florida might believe, air prefers staying in the same place to chasing around. In the above drawing, our needle wiggling along the groove will move a tiny bit of air in contact with it, but that moving air doesn't have enough energy, enough "oomph," to make sound that can be heard throughout the room. If we hook the needle up to a lever, and use the lever to wiggle a thin diaphragm (like a drum head) back and forth, then the diaphragm moving back and forth moves more air, which then has more energy, (more oomph) and can be heard more clearly. This uses more energy. We need to push the needle back and forth harder against the grooves. Pressing harder means that there is more friction. That causes more wear on the record, but we get a louder sound. This is a good thing. But we can't keep making the lever longer and longer, making the diaphragm bigger and bigger, because eventually, we would just snap the needle off. Needles aren't infinitely strong. There has to be another way to turn the small weak wiggles of the needle into a loud sound that can fill a room. To do this, we can use a bit of physics in the form of a horn.

Those big flower shaped horns on old crank up record players weren't just decorative. They were very important to hearing the music. Without the horn, you have to put your ear right up against the diaphragm as though you were listening to a telephone. The horn is critical. A horn works as an acoustic impedance converter. It converts high velocity, low-pressure waves at the wide end into low velocity high-pressure waves at the small end. Or vice-versa, it converts low velocity, high-pressure waves at the small end into high velocity, low pressure waves at the wide end. Look at the diagram. We have a little needle wiggling back and forth, getting some energy from the turning of the record player; (we're literally moving the needle back and forth with the energy from the turning of the record. That is what powers the wiggling.) So, our needle wiggles back and forth, and moves the lever, and the lever wiggles the diaphragm. So far, so good. But the diaphragm moves back and forth fast, literally hundreds to thousands of times a second. (The "A" above middle "C" on the piano requires the needle to wiggle 440 times a second.) So, the air right beside the diaphragm is nearly being torn apart. The pressure spikes up fast, and then, as the diaphragm moves back the other way spikes back down fast. So, you have very high pressures right next to the diaphragm. Now. If we put a properly shaped horn next to it, the horn can take this signal and "spread it out."

If you're a physics geek, the horn acts as an impedance transformer. If you're a poet, the horn takes the thin, reedy sound at the diaphragm and makes it "bigger." This is exactly the same sort of thing that happens in a trumpet or a saxophone. The trumpeter's lips going bzzzzzz make a thin, reedy sound that has no carrying power. The "trumpet shaped" trumpet takes those sound waves and transforms them into Louis Armstrong's powerful music. The sound horn on a record player does the exact same thing. The horn on the record player modifies the output of the diaphragm, making it more listenable.

It has long been known that a trumpet could annoy people a lot further away than a flute. The first record players, (phonographs) used horns that were like cheerleaders megaphones. They were small simple cones. They were adequate for speech, but didn't reproduce highs or lows well. The people building phonographs pretty quickly changed the horn shape. They settled on what turns out to be the theoretically perfect shape - that big-belled flower you've seen in pictures. It's called an "exponential horn." The Grantville developers don't need to know why this shape is best, they can merely copy an existing design, which had been polished by previous trial and error.

We can use the same horn, diaphragm and needle to CUT records if we want to. Attaching a diaphragm across the narrow end of a horn concentrates the sound energy and allows the needle to cut the wiggly line into a piece of wax—or, as in the original, a piece of tin foil wound round a drum (Please look up Edison, Phonograph on the web). So, at this point in our development of a recorder, we're up to where Edison was in his patent. We have a line on a soft surface which exactly follows the movement of the diaphragm (and slightly less exactly the variations of air pressure at the diaphragm, and even less exactly the variations in the room, but it's a start. We can do intelligible speech already).

If we reposition the system and drag the needle back across this groove we'll get a sound at the mouth of the horn which sounds at least a little bit like the original. The problem is, as we do that, it destroys the recording we made. That's not exactly what we're looking for.

If we use a lighter needle/diaphragm assembly, we get a sound much more like the original, and we will be able to play our recording several times before our master wears out. Still, we would like to be able to play a recording many times. We would also like to make many copies of a recording. Even so, the principle of the recording system is simple. We take something soft moving at a constant speed past a needle which is vibrated by the energy from the air. If this something soft hardens with time (like cheese or play-doh) or with varying temperature, or can be treated to harden chemically, or can take a hard, regular surface coating, we have the basis for a permanent medium. Simply dragging a long candle past the diaphragm won't work, however. For two minutes of sound, linear motion requires about fifty meters of candle. Storing and carrying them would be inconvenient. The solution was to coil the recording up some way. Two techniques were tried.

First: Edison's solution: Spin a cylinder and wrap your groove around it like thread on a spool. If you build a drum that you can slide thin cylinders onto, you can "change the records." This has the distinct advantage that the speed of the groove past the needle is constant. It has the disadvantage that making the recording play longer takes more and more "tube." An Edison tube "LP" would be six or more feet long.

Second: The Victrola solution. Use a flat disc (a 'record'). The groove coils from the outside in towards the center. Unfortunately, since the disk turns at a constant angular velocity, when the needle is in the groove near the outside edge, the speed of the groove past the needle is much higher than the speed near the center of the disk. More about that later.

In both cases the play head was moved by the groove itself. Disks became the de facto standard, in the OTL for two simple reasons. They stack better. Tubes have all that annoying space in the middle of them. And they are more copyable. (More on that later.)

Problems remained. The signal had to be fairly loud at the cutting head for anything to record at all (Bessie Smith powering away at the blues in front of a big band gave acoustic levels which are hard to believe in this age of universal amplification) and as to subtle, delicate performances, you can forget about them. Before amplifiers came to be, recording engineers had to constantly balance opposing desires.

On the one hand, they wanted the recording media to have good mechanical stability. A stiff material could accurately record subtle details of the sound. On the other hand, they wanted the recording media to be soft and malleable. Softer material could record weaker, softer sounds.

Similarly, the engineers were torn between higher rotational speeds, which allowed more accurate recording, especially of high pitched sounds, and lower rotational speeds to extend playing time. Placing the grooves closer together also extended playing time, however, wider groove spacing allowed bigger wiggles to be recorded, and thus, louder sounds. Larger discs extended playing time, but increased storage and transport difficulties. It was in everyone's interests to have a standard. The standard that was settled on was ten to twelve inch disks spinning at 78 RPM. A lot of interesting (loud) music was recorded like this.

Let's return to the advantages of disks. If you record on tubes, they are very hard to copy. Each tube has to be recorded individually. Bessie Smith had to belt out another one for every record sold. Good for Bessie, regular employment. Actually, not that good for Bessie. It was a boring, hard, low-paying job. (Of course, in the New Time Line, we won't be recording Bessie directly, we'll be recording a recording of Bessie. Still, it's not the best alternative.)

On the other hand, disks can be "pressed." When the recording process was finished, the master was cleaned of any small bits left over from the cutting process, coated with graphite, and plated with metal. This gave a negative of the original which could be used to produce multiple copies. In the case of popular artists, the process could be duplicated again and again. That way you could have sub-masters and archive masters. This was necessary since the masters could only be used a certain number of times.

Record players in houses had steel needles or blackthorn thorns attached to a diaphragm. The diaphragm was located in a cavity leading to a horn. The narrow part of the horn was hinged so that the playback needle could track the groove, or be lifted off and folded back to change the disc. The horn was made as large as practical. It was often built into a large cabinet like a sideboard or hutch, coiled back on itself and filled the furniture. The larger the horn, and the slower its flare rate, the better the bass response. Just like up time, speakers with big booming bass have to be large. The same is true of horns in mechanical players.

It is important that the speed be constant or the music goes Wow-wow-wow. This is considered bad. Constant speed was controlled by a centrifugal rotating watsit. The watsit reduced power when the arms swung out to a predetermined point. It's probably easier to copy the speed governor in an existing mechanical phonograph than to reinvent it. It is far less complicated than a watch. Many of these mechanical record players were still in use in the 1950s, half a century after the invention of the vacuum tube. Victrola's may not produce the great sound of modern CDs, but people were happy with the results and could listen to their favorite artists at home without paying a months salary to go to a concert (assuming there was a concert on) Still, one couldn't say that the illusion of "being there" was excessive.

At the beginning of the twentieth century came the next major development—the thermionic valve, or vacuum tube. 1907 saw the triode, and gave us electronics. Electronics was important, even if the players were still mechanical. Recording engineers could now start building decent microphones and amplifying them up to reasonable levels. They were now able to amplify quieter music and cut records electrically. Early electrical cutting heads look a lot like the old mechanical ones (with the horn removed, of course) but the diaphragm is made of iron, moved by an electromagnet which is driven by an amplifier.

As the engineers started to use electronic recording heads, they noticed a that the electricity flowing through the head caused it (and the needle) to get warm. The engineers kept increasing the electric power to the head so that they could increase the amount of back-and-forth wiggle. This let them cause the cutting needle to more and more accurately follow the real sound waves in the air. The more power they had, the less the stiffness of the medium mattered. They could force that little needle to wiggle the way they wanted.

The more power they put in, the hotter the needle got. Hot cutting heads became common. This turned out to be a good thing. The hot needle softened the recording substrate, and made it easier to cut the record exactly the way they wanted. After the hot needle passes the disk cools and hardens again. Of course, if the cutting head gets too hot, it melts the solder and the disk under it, so high power cutting heads have to be cooled with pipes of water or oil.

There are two advantages to the hot cutting head. One: the records sound better because they more accurately track the sound from the microphone. Two: we can use harder cutting blanks. With harder cutting blanks it becomes possible to play our cuttings (not too many times) and check that what we recorded is what we wanted.

Even if the majority of people were still listening to them on acoustic gramophones, the range of what could be recorded had gone up enormously. Glenn Miller could play some mezzo pianos, rather than being stuck in forte and above. We, by using the modern electronics we have available, can use two microphones, one for the band and one for the vocal. Politicians speeches can be retained for posterity (no advance can be all positive). Radio broadcasts can be recorded during the transmission, and rebroadcast ad nauseam without having to pay the performers again, a golden age!

What follows is one man's attempt to design a record mastering facility for Grantville. It presumes that the mechanical gramophones described above are being produced, and that a market for the classic 10" and 12" 78 rpm disc recordings exists. This design concentrates on the cutting room, since the earliest records will mainly be reissuing pre-existing recordings from up-time recordings. Our recordings of up-time CD's are going to be the best recordings we produce. They will be better in all ways than down-time reproductions of those same songs, simply because of the quality of the sound. Eventually, though, down-time composers will arrive in Grantville, eager to have their music be distributed by the new network of record stores and dealers. Even when producing records of down-time compositions, they will be recorded to tape or hard disk and then cut rather than cut live as long as our tape recorders and computers continue to function. The cutting studio will be equipped with the most reliable amps and speakers we can get. There is no reason that the up-time components of our cutting studio shouldn't function for thirty years or more.

The record cutting lathe is going to be expensive, and will take some machining, but it's a one off job (maybe two or three if this really takes off, but minor, anyway).

Start with the turntable. This is what will hold the record blank we will be cutting. It needs to be heavy, perfectly balanced and dead flat. It can be specially machined if necessary, but we should be able to find something. Perhaps a brake drum from something large? In any event, there is a 14 inch flat circular plate that will hold our record blank. It needs to be heavy so that it acts as a flywheel. As the cutting head cuts, the heavy turntable keeps the speed constant while the pressures change. Also, heaviness helps control any changes caused by variations in power reaching the turning motor.

Directly below the turntable is the bearing that supports it. We need one really good bearing, as rumble free as can be managed. We're recording in mono, so rumble problems are reduced, but the cutting head is pressing down forcefully on one side of the rig, with nothing balancing it on the other. If the bearing isn't perfectly smooth, as it grinds and rumbles, those sounds would be cut into the record. It's very important to avoid this.

To the right of the turntable and its bearing is the motor. The motor is going to be very oversized. This will ensure that it will run at a constant speed because the strain of cutting is small compared to the mass of the motor. Up-time, the motors for cutting lathes are hysteresis synchronous or feedback controlled. Although those are better, a big, powerful, simple three phase motor is more likely to be findable than anything sophisticated, and it saves us trying to design the fancy controls to go with the fancy motor we don't have.

The geeks are going to ask: How do we measure the speed of the turntable? The tuned reed technique is good for checking the frequency of the motor drive current, but short of sticking a series of fridge magnets round the rim (not, I suppose, impossible) it doesn't work for the turntable. There is another simple answer. Strobe markings round the edge combined with a light source driven by a known frequency (perhaps a tuning fork) should work as long as the lathe is not in sunlight.

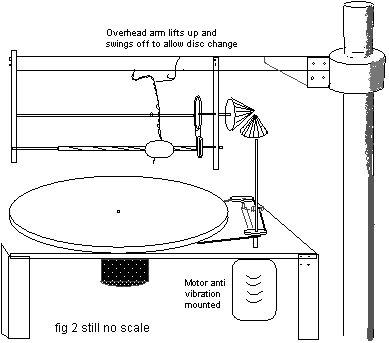

The cutting head has to be held just over the blank record, and moved to the side as the record spins so that it cuts a spiral groove. The mechanism holding the cutting head must be very rigid and accurate. What we do is suspend the cutting head from an arm, and run a threaded rod through the carrier. The carrier is machined to engage with the threaded rod, and an overhead bar improves rigidity and carries the flexible cabling and cooling fluid to the cutter head. A vertical shaft and gears carries the rotation of the motor up to the rod so that everything moves together. All this stuff is heavy, carefully machined and fussy, but as we said, we only have to make one.

Everything is open for ease of cleaning and maintenance, rather than enclosed for protection, which means that if the operator has long hair, he or she wears a hair net. There will be no baggy clothes, nothing that can get caught in the mechanics. This thing will fail any health and safety inspection, so operators have to be careful. We don't want any scalps clogging up this mechanism.

The fanciest bit is going to be the cutting head and drive electronics. The easiest thing to modify into a cutting head we have is the speaker assembly from an old telephone handset. It has a moving iron driver that is simple to attach a needle to. The telephone handset has some problems; it's somewhat low power for the purpose, has higher impedance than would have been optimal, and it doesn't heat the cutter as much as I would like, while overheating itself too easily, finally because we've (oh, all right—I've) selected a moving iron design, very little of the heat is conducted to the cutting point where it would do some good.

Cutting heads on late generation stereo LP lathes were frequently cooled with liquid nitrogen, which gives an idea of how much heat is generated. So I'm going to damp out the cavity with some high temperature lubricating oil. I'll install a thermostat and a pump to move the oil around when the temperature goes above reasonable. Also mounted on the cutting head will be a sensor wire (for the temperature), a pair of flexible plastic pipes carrying heating/cooling oil, a vacuum cleaner tube to suck off the swarf, power wiring for the needle heater, and hopefully a microscope to check the groove (nothing too esoteric, a child's first biology set, maybe even a reading lens—I get enough magnification by taking my glasses off). None of these, nor the second lightweight arm for checking cuttings are marked on the diagram, to avoid it becoming too muddled—a photograph showing the final setup would be virtually incomprehensible.

One of the hardest things for a recording engineer cutting records is to keep the signal to the cutting head adjusted so that the groove doesn't cross over itself. If the needle wiggles too far, the grooves can touch, allowing the record to skip. Limiting the dynamic range of a modern digital master to what is available on our somewhat less sophisticated final medium is going to have to be manual at first. The cutting engineer will be doing three or four rehearsals with current running through a meter, but the cutting head will not be in contact with the disc. The engineer will be raising and lowering the volume control to compensate for the differences in level of the original. This is a major advantage with pre-recorded material. If this were a direct recording with musicians, we would have to cut lower levels so as not to risk the groove crossing over into the adjacent one

The cut lacquer master disc is brittle and would wear out if played much, so the next stage is to make a metal master from it. A thin finish of graphite or silver is applied to the master and used as a conductive element to allow electroplating. The electroplating is done slowly to avoid softness or sponginess. The longer you run the electroplating system, the thicker the plate. In this case plating continues to an unusual thickness, which will take hours to weeks. Then you remove the lacquer master and you have a stamp. Put the stamp on a hot iron plate and you can stamp out records like a printing press.

Now let's make records. We take our copper negative and attach it to a rigid iron plate, so it doesn't deform under pressure (These plates used to be mass produced. I once met a crate of them and thought it would require antigravity to shift it) Since we want to hot press, we mount a good thermostatic hot plate and a thick copper plate to get an even distribution of the heat with a short spike mounted in the middle to keep everything centered

I propose that we make our records single sided on a turned hardwood disc. The disc should be about a quarter inch thick. I suggest the hardwood, first, because wood is easily and rapidly machined and quality woodworkers are easier to find than, say, plastics people. Second, the wood is tougher weight for weight than anything else we're likely to find and transports well. I suggest that the hardwood disc will be less expensive than many other materials. If the hardwood is well seasoned and coated with the same lacquer we're using to press to, the discs shouldn't warp.

So, we've got a nearly disc size lump of lacquer, preheated till it's soft, and a slightly oversized varnished wooden disc. We squeeze the lump onto the plate, and it forms into the grooves in the copper master, and bingo! We've got a record.

For testing, we need a decent playback system on hand. This will probably not be a mechanical transport—one of our standard export turntables—but a light modern pickup arm and cartridge, equipped with an oversize sapphire needle (if available—if not we screw in a metal needle) so we can play finished discs with minimum wear. Certainly the first of any series of records will be played end to end, as soon as it is sufficiently cool and before we start pressing the series. We'll want to compare it with the original recording, to make sure it sounds right. From then on, a certain percentage will be tested, just to know when the mold is wearing out and needs replacing, or the lac is going bubbly, or the lubrication needs to be more frequent or any one of a thousand other problems.

I've glossed over a hundred problems with the process I described. There will be problems of cleanliness (medieval clean room conditions), of finish, homogeneity of mixes of ingredients, labeling and packaging, of getting surfaces into decent thermal contact (electroplating gives a rough, lumpy finish which will have to be smoothed before mounting in the press—but without deforming the grooves on the other side), of waste material that needs cutting off without either deforming or dirtying the disc. All of this needs fastidious care, but is fairly obvious. Since individual discs can carry about five to seven minutes of music, or perhaps nine or ten minutes of speech, the labeling and transport of a symphony or a Shakespeare play is a non-trivial exercise, but it's all standard problems, nothing special.

I find I have filled my allotted space with transfer of already recorded material. Recording new original material will have to come in a later article (if anyone is still interested).

Finally, I cheated in this article. I wrote it entirely from memory, as if I were there, but discovered certain gaps in my knowledge, which I filled by looking up details on the web. The following sites I found particularly interesting.

www.recordcollectorsguild.org 1

www.recording-history.org/HTML

1857—Leon Scot in France demonstrates the Phonoautograph system for recording sounds. It uses a diaphragm flexible enough to respond to strong sound waves, attached to a fine stylus, which presses against a glass plate, cylinder or disc. In the cylinder form of the device, the glass cylinder was coated with black carbon (smoke) and rotated, recorded sound as a wavering line.

1877—In July, Edison files his first patent in Great Britain on a sound recording and reproduction of sound. A full specification for the phonograph was filed in April, 1878.

1878—The first 600 or so tin foil phonographs are made by several small machine shops at Edison's request. These were distributed to demonstrate the principle of phonography

1886—Alexander Graham Bell and an assistant, C. S. Tainter, patent important improvements on Edison's original phonograph. They call their machine the Graphophone

1889—January—Columbia Phonograph Co. begins its commercial life, based on the patents of the earlier Graphophone Co. Before 1894, Columbia and the Edison company are part of North American Phonograph, but later they split to become rivals. Both companies begin selling phonographs for use as dictation machines

1894—Emile Berliner introduces the Gramophone in the US (1889 in Europe), using a disc instead of a cylinder and a groove cut from side-to-side (laterally cut) instead of Edison's "hill and dale" (vertically cut) method. [Edison had experimented with discs in 1878, but decided not to use them, and many believe that the vertical cut method resulted in better sounding records]. The Gramophone is aimed at the entertainment market, and home versions are not capable of making recordings.

Victor Talking Machine Company formed

1906—Victor Talking Machine Company, a relatively recent entrant, offers its first "Victrola," a disc phonograph [we use the term phonograph generically from this point on] which placed the horn inside the cabinet instead of outside it

1907—An early attempt at sound amplification, the Parson's Auxetophone, used compressed air to increase the action of the diaphragm in phonograph reproduction

1912—Edison, at long last, begins offering disc type phonographs and records for sale, in recognition of the large number of discs on the market. Cylinder machines and records, however, are still produced until the demise of Edison's Entertainment Phonograph division in 1929.

1924—In October, Columbia Records experiments with "electrical" recording equipment developed by Western Electric. Electrical recording employs electronic amplifiers, microphones, and electromagnetic record cutters.

1925—Victor releases its last phonograph disc made by the original acoustic process. Thereafter, it uses electrical recorders and releases the discs under the name Orthophonic.

1926—Edison announces a long-playing, 12 inch disc capable of holding 20 minutes of music per side. This format does not become a commercial success. In 1927, the company markets its first electrically-recorded discs.

1927—Edison offers a phonograph capable of reproducing either Edison vertical cut discs or his competitors' more popular lateral cut discs.

1929—Edison introduces a series of electrically recorded, lateral cut discs, a reflection of the increasingly marginalized market for acoustic and vertically-cut records.

1929—Edison ceases production of vertically-cut records and pulls out of the home phonograph business. Thomas A. Edison, Inc. continues to be a major force in the dictation equipment business, and continues to use cylinders through 1945

1931—RCA Victor introduces its version of the long playing disc, which is also a commercial failure (see entry for 1926)

1948—Columbia Records introduces the 33 1/3 rpm Long Playing record disc

1949—RCA Victor introduces its 45 rpm disc and a special record changer on which to play them.

Circa 1950—Introduction of 16 rpm discs for books-on-disc, recorded voice releases, etc.

1631—No energy available for non-survival based projects

1632—The press could be built in a week, with minimal up-time labor required. However, with nothing to press, and no machines to play it on anyway, this would be a bit futile. The electroplating baths need to be set up as fast as possible. It would be worth getting hold of some old 78 rpm discs, and start by duplicating these, before the cutting lathe is ready, as no-one has any experience in this field (and OTL many decent cuts were spoiled by inadequate electroplating, including a couple of mine). The room in which we're going to be cutting is chosen, and structural members mounted. Probably the old Victrola machine will be stripped, tested and measured (dimensions and performance). If several machines are available, all of them undergo this treatment, and third angle diagrams are copied onto tracing paper for comparisons of different models.

1633—The lathe is built into the room, and the electronics wired and tested. First test cuttings are done, listened to and adjustments made (adjustability—bolts rather than welds, variable heights, weights, pressures are to be built in everywhere. Even if this is a production facility, it's a test bed, too—perfectibility, not ultimate design is our watchword) Prototype turntables leave the machine shops, are assembled and tested, and a price for the production run worked out. Tests are done on bubble free production of shellac, both with and without carbon filler. All of this goes on in parallel, and shouldn't require more than a couple of months. It does require rather a lot of up-time help, so there might be some big gaps in the process while essential contacts are otherwise occupied. I don't know what machines will be necessary for building the turntables, but having a set of these machines built and training a team of down-timers in their use is a high priority. Castings for turntables will be needed. Also, cabinet makers must be contacted. We'll have to explain why they have to use twice as much glue as for anyone else (a rattle or buzz in one of these units is intolerable). Where is felt available? The enthusiast who started all this is by now sleeping three hours a night, eating only socially, divorced from friends and family as well as spouse and offspring, and, in future years will look back on this period with nostalgia—which says something about humanity, but I'm not sure what.

Then the dead period. Everyone's working, things are happening. The first turntable has come off the production line, the first records have been pressed, there are no immediate disasters, but nothing much is being sold because, for the time being, there's nothing much to sell. After the previous hysteria the lack of adrenaline leaves everyone suspecting they've died, and just not noticed.

1634—Having a phonogram in the corner of your withdrawing room, and five or six discs, is the fashion accessory. Only those who are disgustingly rich and progressive need apply. Music conservatories are begging their rich patrons to obtain them one. Crises as excess demand tends to erode quality control. Quantities are still small enough that transport is not yet a problem, but the search for cabinet makers in Italy and France, capable of getting the acoustics right while adapting the aesthetics to the local market, and incidentally meaning that only the mechanics need to make the long voyages. Explaining what is going on to a woodworker, who doesn't speak any language you do, has no idea what makes sound function, works to a different measurement standard, and, worst of all, has several days travel to ask a question—well, challenging might not be an adequate term. Composers are already begging studio time to immortalize their creations—and the recording section is still at the "Mary had a little lamb" stage.